3D printing has taken the world by storm, unleashing a torrent of creativity and innovation. But what happens when your masterpiece comes out in pieces? Fear not, intrepid creators! The art of attaching 3D prints is here to save the day.

From simple glues to fancy snap-fit connectors, there are more ways to join 3D printed parts than there are cats on the internet. Whether you're building a life-size robot or just trying to fix that mug you accidentally sat on, this guide will have you connecting prints faster than you can say "layer adhesion." So grab your favorite beverage, put on your thinking cap, and prepare to become a master of 3D print attachment!

1) Superglue: The universal fixer-upper, because what can it not do?

Ah, superglue - the magical adhesive that can stick just about anything together, including your fingers if you're not careful! This wonder substance is a 3D printing enthusiast's best friend.

Superglue, also known as cyanoacrylate adhesive, is fast-bonding and high-strength. It's like the superhero of the adhesive world, swooping in to save the day when your 3D prints need a quick fix.

Got a small part that snapped off? Superglue to the rescue! It bonds almost instantly, giving you more time to admire your handiwork and less time holding pieces together.

But wait, there's more! Superglue comes in different consistencies. Thick glue or gel works great for vertical surfaces, ensuring your 3D printed wall art doesn't become floor art.

And if you accidentally glue your fingers together? No worries! A cotton ball soaked in acetone can help you escape your sticky situation. Just remember, it's superglue, not super-get-out-of-glue!

2) 3D Gloop: Sounds like a blob, sticks like a champ.

3D Gloop might sound like something a kid would make in science class, but don't let the name fool you. This sticky substance is no joke when it comes to attaching 3D prints.

It's like the superhero of adhesives, swooping in to save the day when other glues just can't cut it. Imagine if Spider-Man's web-shooters were filled with this stuff - buildings would never fall apart again!

3D Gloop works on a variety of materials, making it a versatile sidekick in any maker's toolkit. It's so strong, some say it could hold together a relationship between a cat and a vacuum cleaner.

But be warned: using 3D Gloop is not for the faint of heart. It requires proper ventilation unless you want to feel like you're in a cartoon where the characters get dizzy from sniffing glue.

While it might be pricier than other options, 3D Gloop's strength is no joke. It's like the Hulk of adhesives - small amount, big impact.

3) Epoxy: The power couple of chemistry - strong and reliable.

Epoxy is like the superhero duo of the adhesive world. It's Batman and Robin, but with less spandex and more sticking power. This dynamic duo consists of two components that, when mixed, create a bond stronger than a bodybuilder's biceps.

Epoxy resins are the Clark Kent of adhesives - mild-mannered until they meet their hardener counterpart. Then, kapow! They transform into a super-strong substance that can hold your 3D prints together like they're in a bear hug.

Applying epoxy to 3D prints is easier than teaching a cat to fetch. Just mix the two parts, spread it on your pieces, and press them together. It's like making a sandwich, but instead of bread and cheese, you're using plastic and chemical reactions.

Once cured, epoxy forms a bond tougher than a drill sergeant at boot camp. Your 3D printed creations will stick together through thick and thin, in sickness and in health, till death (or a really big hammer) do them part.

But be warned: epoxy has a mind of its own when it comes to setting time. Some types harden faster than a deer in headlights, while others take their sweet time, like a sloth on vacation. Choose wisely, or you might end up stuck... literally!

4) PLA Filament Welding: Hot and... melty? Yes, melty.

Who knew that melting plastic could be so much fun? PLA filament welding is like playing with a tiny, high-tech hot glue gun. It's perfect for those who enjoy a bit of controlled chaos in their 3D printing adventures.

The process is simple: heat up some PLA filament and use it to stick your prints together. It's like making s'mores, but instead of marshmallows, you're roasting plastic. Yum!

There are a few ways to get your PLA nice and gooey. Some brave souls use a soldering iron to melt the filament directly onto their prints. Others prefer the more refined approach of using a 3D pen to draw their welds with precision.

For those who like to live dangerously, there's the friction welding method. Just chuck a piece of filament into a drill and spin it against your print until it melts. It's like giving your 3D prints a hot plastic massage!

Remember, PLA welding is not for the faint of heart. It requires a steady hand, a good sense of humor, and a willingness to embrace the occasional blob of molten plastic.

5) ABS Juice: Not a health drink, but your prints will stick together like they're soulmates!

ABS juice sounds like a trendy health drink, but it's actually a secret weapon for 3D printing enthusiasts. This magical concoction is made by dissolving ABS plastic in acetone, creating a sticky solution that bonds ABS prints together.

To whip up this plastic potion, makers can use about 10 ounces of acetone and 8-10 strips of ABS filament. A quick shake, and voila! The juice is ready to work its adhesive magic.

Applying ABS juice is like giving your prints a love potion. They'll stick together so well, you'd think they were meant to be. It's perfect for joining separate pieces or patching up broken parts.

But beware! This juice isn't for drinking. Unless someone wants their insides to become a 3D-printed masterpiece, it's best to keep it away from curious sippers.

For those looking to create an even stronger bond, they can try making ABS slurry. It's like ABS juice on steroids, with a higher ratio of ABS to acetone. Talk about relationship goals for plastic parts!

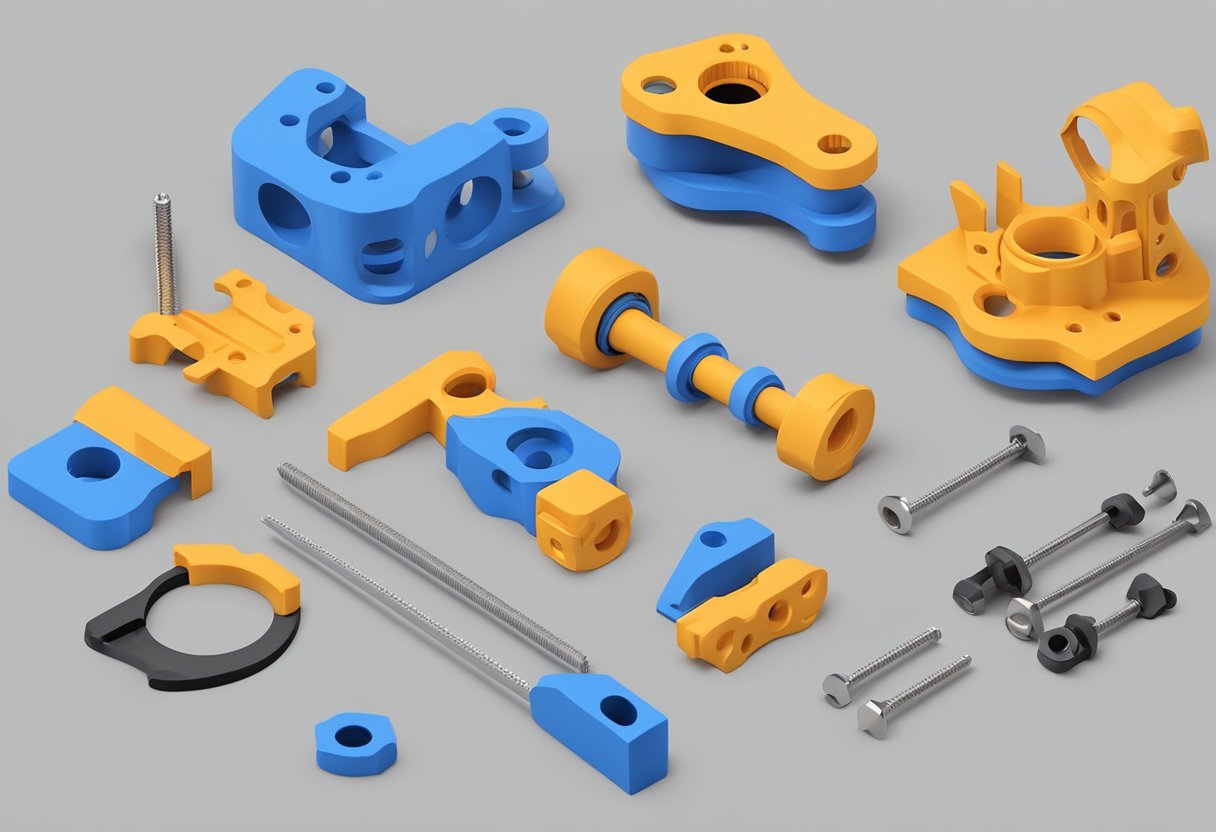

6) Screws and Nuts: The classic hardware romance.

Ah, screws and nuts - the Romeo and Juliet of the hardware world. These star-crossed lovers have been holding things together since before 3D printing was even a twinkle in an engineer's eye.

When it comes to joining 3D printed parts, this dynamic duo doesn't disappoint. They're like the peanut butter and jelly of the maker world - a classic combo that just works.

To use screws and nuts, designers need to create holes in their 3D models. It's like making little apartments for these hardware lovebirds to move into. How romantic!

The beauty of this method is its strength and adjustability. Makers can tighten or loosen the connection as needed, like a relationship counselor for plastic parts.

But be warned - using screws and nuts can be a bit like playing matchmaker. It takes some trial and error to find the perfect fit. Too loose, and your creation falls apart. Too tight, and you might crack the print.

Remember, size matters when it comes to screws and nuts. Choosing the right dimensions is crucial, much like picking the perfect outfit for a first date.

7) Soldering Iron: For prints that want their connections iron-clad

Who needs glue when you've got a mini lightsaber? A soldering iron can turn your 3D prints into one solid piece faster than you can say "ouch, that's hot!"

This tool isn't just for fixing grandpa's old radio. It's perfect for smoothing 3D prints too. Just don't try it on your plastic action figures - they might not appreciate the makeover.

To get started, grab a soldering iron and pretend you're a sculptor. Gently press the tip against your 3D printed parts and watch the magic happen. The plastic melts faster than ice cream on a hot summer day.

But wait, there's more! You can even use this method to insert threaded components into your prints. It's like giving your creation a fancy metal piercing.

Remember, practice makes perfect. Start with scrap pieces before tackling your masterpiece. And please, keep your fingers away from the hot end - unless you want a very unique fingerprint.

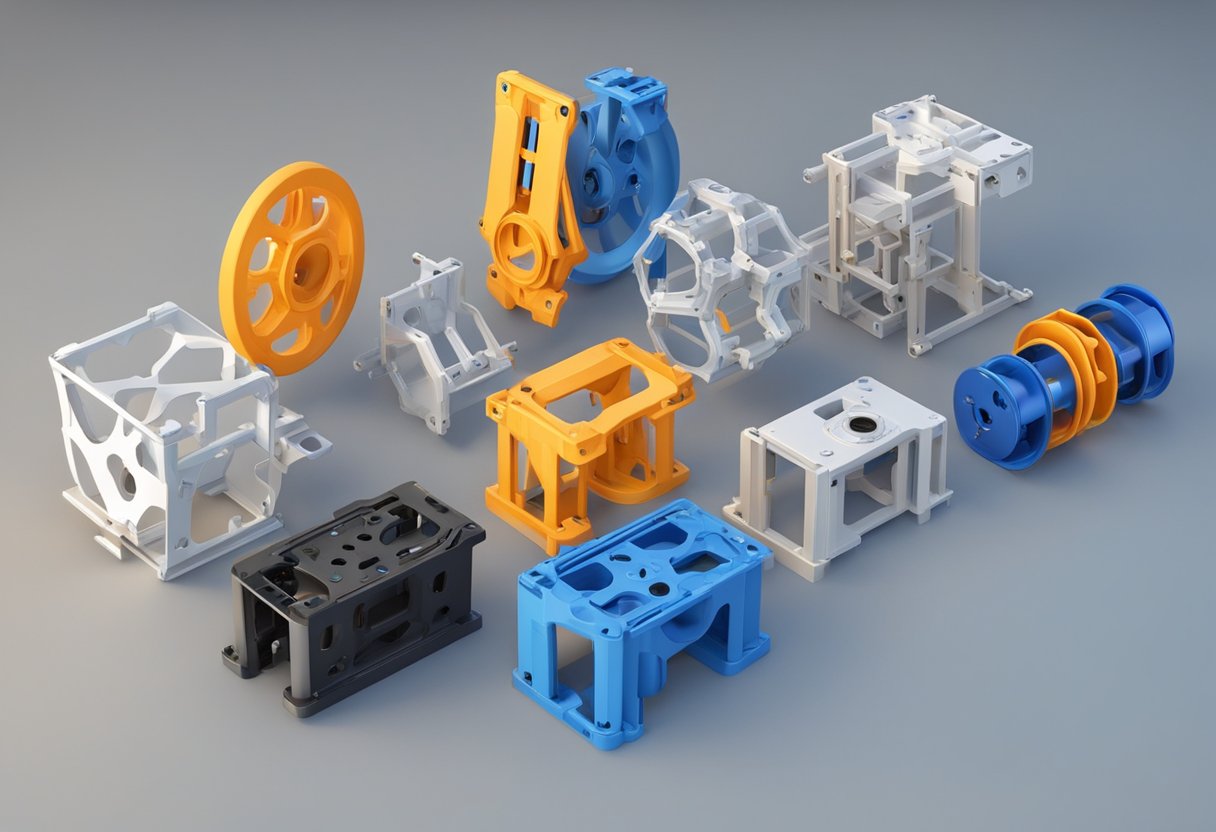

8) Brackets and Clips: Because holding hands isn't just for humans.

Brackets and clips are the matchmakers of the 3D printing world. They bring pieces together like a romantic comedy, minus the awkward first date.

These little connectors are the ultimate wingmen for your 3D prints. They swoop in, grab hold, and say, "You two belong together!" Who knew plastic could be so sentimental?

Snap-fit connectors are the speed-daters of the bunch. They're quick, easy, and make a satisfying click when they find their perfect match. It's like love at first snap!

For those prints that need a little extra support, there are mounting clips. They're like the protective parents of the bracket world, making sure your creations stay put.

And let's not forget about hinges. They're the flexible friends in this relationship, allowing your prints to move and groove without falling apart. It's like couples yoga for plastic!

So next time you see two 3D printed pieces holding tight, remember: it's not just attachment, it's true love. Brackets and clips - bringing inanimate objects together since the dawn of 3D printing.

9) Velcro Straps: When your prints need a little flexibility in their lives

Who says 3D prints have to be rigid all the time? Sometimes they just want to let loose and get a little bendy. Enter Velcro straps, the party animal of the attachment world.

These handy little fasteners are perfect for when your prints need a quick outfit change. They're like the sweatpants of the 3D printing world - comfy, adjustable, and always ready for action.

To attach Velcro to your 3D prints, start by giving the rough side a good slathering of glue. It's like putting sauce on a pizza, but less tasty and more sticky.

Once you've got your Velcro all glued up, press it onto your print and hold it there like you're giving it a tiny hug. This helps make sure it stays put and doesn't try to make a break for it.

Remember, Velcro comes in pairs, like socks or bad jokes. So don't forget to stick the other half on whatever you're trying to attach your print to.

With Velcro, your 3D prints can now enjoy a life of easy on, easy off relationships. It's perfect for those indecisive prints that just can't commit to a permanent connection.

10) Dovetail Joints: A puzzle piece bond for your 3D masterpiece

Who says carpentry gets to have all the fun? Dovetail joints are like the cool kids of the 3D printing world. They're the puzzle pieces that make your prints go, "Hey, we belong together!"

These nifty joints feature interlocking "tails" and "pins" that fit together snugger than a bear in hibernation. It's like your 3D prints are playing a game of "connect the dots," but way more exciting.

Dovetail joints are strong and visually appealing. They're the Superman of connections - not only do they look good in tights, but they're also incredibly sturdy.

Designing these joints is like being a matchmaker for your 3D prints. You're basically setting up two pieces on a blind date, hoping they'll hit it off and stick together forever.

Remember, when it comes to dovetail joints, size matters! Too tight, and your prints will be playing hard to get. Too loose, and they'll be sliding into each other's DMs all day long.

So, next time you're looking to connect your 3D prints, consider the dovetail joint. It's the perfect way to make your creations say, "I dove right in, and now we're tail-made for each other!"

Understanding 3D Prints

3D prints come in all shapes, sizes, and materials. Knowing your print's makeup and how it behaves is key to successfully sticking things together without creating a sticky situation.

Materials and Compatibility

Ever try to glue oil and water? Yeah, didn't work out so well. The same goes for 3D prints. Different plastics play nice with different adhesives. PLA, the darling of 3D printing, loves a good superglue party. ABS, on the other hand, prefers to get cozy with acetone-based adhesives.

But wait, there's more! Some filaments are like cats - they just don't want to stick to anything. TPU and other flexible filaments can be real party poopers when it comes to bonding.

Snap-fit connectors can save the day for tricky materials. They're like puzzle pieces for grown-ups!

Strength and Durability Factors

Let's talk about strength, baby! When joining 3D prints, you want a bond stronger than a bodybuilder's biceps. The layer orientation of your print can make or break your bonding dreams.

Prints are strongest along the X and Y axes, but weaker in the Z direction. It's like trying to separate pages in a book versus ripping it in half.

Surface prep is crucial. Rough it up a bit - your prints need some texture to grip onto. Think of it like giving your pieces a tiny mohawk.

Temperature matters too. Some adhesives work best when things get hot and heavy. Others prefer to chill. Know your glue's sweet spot for the strongest bond.

Techniques for Joining 3D Prints

Joining 3D prints can be a real head-scratcher sometimes. But fear not! There are plenty of ways to stick those plastic parts together without losing your marbles.

Adhesive Options

Who knew glue could be so exciting? It's like matchmaking for plastic! Super glue is the speed-dating champion of adhesives, forming bonds faster than you can say "3D printing."

For those who like to take things slow, epoxy is the romantic dinner date of glues. It takes its sweet time but forms a bond stronger than a superhero's grip.

Don't forget the unsung hero of the adhesive world - UV resin. It's like magic in a bottle! Just apply, shine a UV light, and poof! Instant connection.

Interlocking Designs

Why bother with glue when your prints can do the tango? Interlocking designs are like puzzle pieces for grown-ups.

Snap-fit connectors are the cool kids on the block. They click together with a satisfying snap that's music to a maker's ears.

Dovetail joints are the classy gentlemen of connections. They slide together smoothly, like a well-rehearsed dance move.

For those who like a bit of flexibility, hinges are the way to go. They're the yoga instructors of the 3D printing world, keeping things bendy and fun.

Mechanical Fastening Methods

Sometimes, you just need to get down and dirty with some good old-fashioned hardware. It's like giving your 3D prints some fancy jewelry!

Screws are the workhorses of mechanical fastening. They hold things together tighter than your grandma's hugs.

Nuts and bolts are the dynamic duo of connections. They're like the Batman and Robin of the fastening world, always ready to save the day.

For a quick and easy solution, try heat-set inserts. They're like tiny hot tubs for your screws, melting into place and creating a cozy home for your hardware.

Member discussion